Our patented Rotary Brush System for multi-screen separators consists of a brush system and mobile chassis. Rotary brush operates independently to the separator at low rpm. Lumps are broken apart by horizontal scraping motions and vertical crushing motions between the brush and screen. Particles too large to pass through are brushed aside to prevent clogging of the screen, improving efficiency and productivity of easily clustered material.

РЌЈ Separate and de-lump - suitable for raw, unrefined products with higher size distribution and impurities. Capable of light breaking and separating in one unit, vastly increases productivity.

РЌЈ Mobile and adjustable - mobile chassis allows quick relocation. Brush can be raised for fast screen change, cleaning, and maintenance.

РЌЈ Simple operation - controlled independently from the separator, via an easily operated control panel.

РЌЈ Durable, brush does not damage screen - brush does not make contact with screen, prevents early wear and tear.

РЌЈ Stainless Steel - all contact parts in stainless steel SUS304. Full or partial SUS316 upgrades available.

РЌЈ Variable speed brush available.

Ideal for products that are:

РЌЈ High water content, high moisture level.

РЌЈ High oil content.

РЌЈ Unrefined products with a mix of impurities and higher size distribution.

РЌЈ Products that form lumps easily.

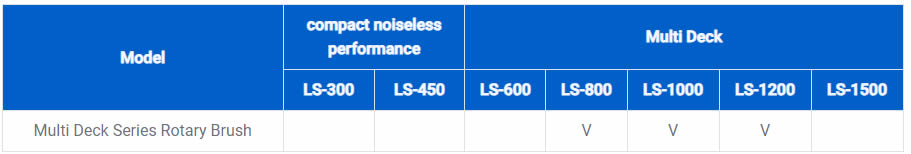

Applicable models