Designed for high-capacity, continuous separation, the LS multi deck model is suitable for wet/dry, grading, classification, de-dusting, and quality control. The multi-purpose model is essential to improve quality and safety of production materials, increase productivity, and reduce cost and labour.

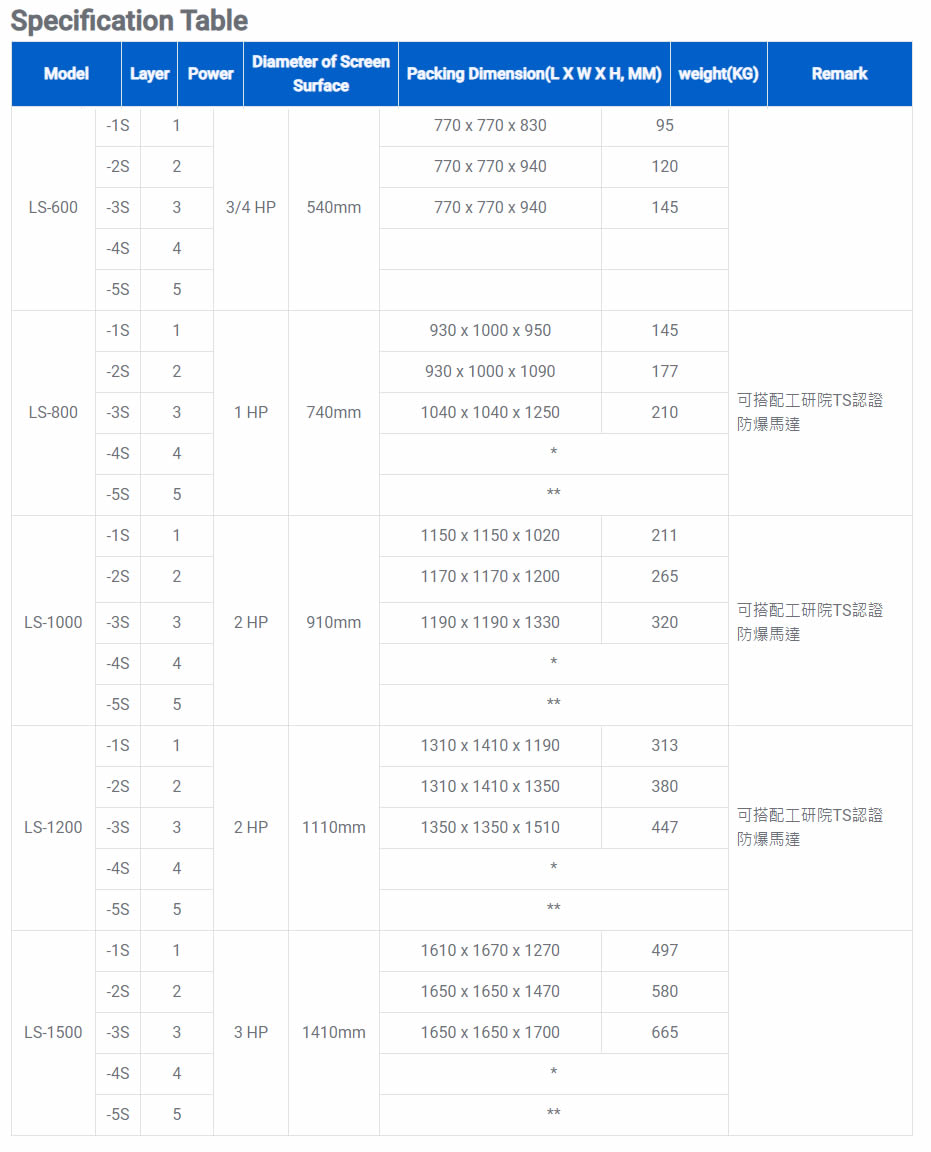

Continuous development along with various available add-ons, makes the LS multi deck model a versatile unit capable of separation up to 6 classes (5 screens).

РЌЈ Wide range of sizes and modifications available to suit all types of powder and viscous liquids.

РЌЈ Stainless Steel - all contact parts in stainless steel SS304. Full or partial SS316 upgrades available.

РЌЈ Simple and efficient РђЊ higher capacity, low maintenance, lower noise, and require minimal floor space compared to other conventional separators

РЌЈ Lower energy consumption

РЌЈ Light weight - easily movable with pellet jack or forklift.

РЌЈ Highly durable - designed for continuous operation with minimal service required.

РЌЈ Anti-binding devices - prevent screen clog without creating dust clouds during operations.

РЌЈ Automatic discharge of separated materials - continuous and uninterrupted production.

РЌЈ Up to 5 screens per unit - allowing multiple separations with just one unit for cost effective operation.

РЌЈ Quick change design - allows screen change in less than 5 minutes.